High-Performance Flexible Hoses Supporting Sustainable Mobility

FAB FOR HOSE, together with its new engineering division H4H (Hose For Hydrogen), offers its expertise to design, produce, and support the development of silicone and EPDM hoses for Fuel Cell Vehicles (FCV), Battery Electric Vehicles (BEV), electrolyzers, and the hydrogen energy industry.

Why Silicone?

Silicone is an ideal material for FCV, BEV, and electrolyzer systems due to its unique advantages:

- Resistance to extreme temperatures: handles both heat and cold effectively.

- Safety and electrical insulation: provides excellent protection against electrical risks.

- Durability and flexibility: ensures a long lifespan and easy installation.

- Compatibility with fluids: suitable for electrical fluids and coolants used in electric vehicles.

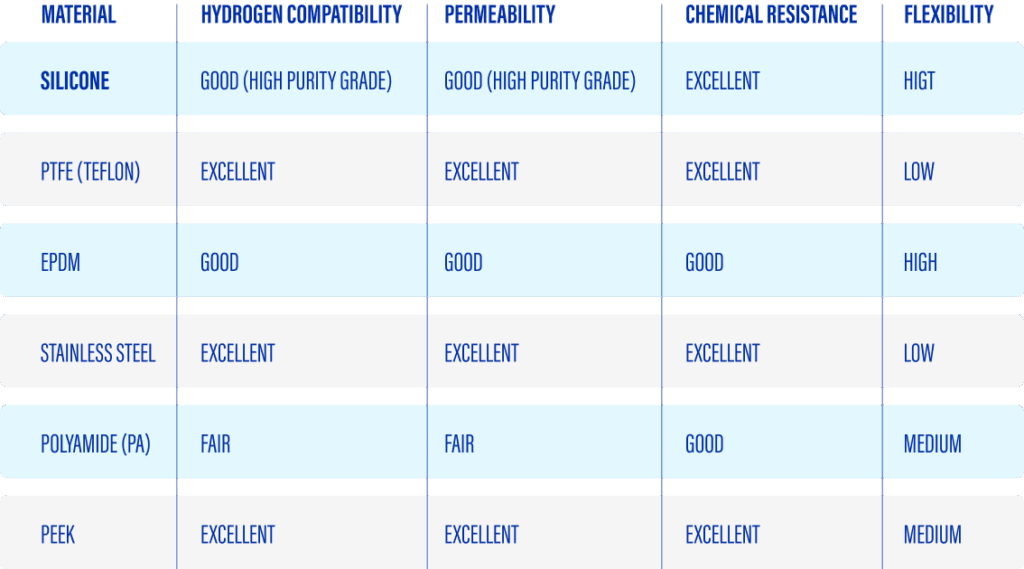

Chemical Compatibility Table

The Fab Lab team is committed to researching, developing, and producing high-performance silicone solutions tailored to the needs of hydrogen and electric mobility industries. Our expertise covers the following key application areas:

Fuel Cell Vehicles FCV

Our custom-engineered silicone hoses are specifically designed for Fuel Cell Vehicle systems, ensuring reliability and performance in hydrogen-powered applications.

- Ultra-high purity materials prevent contamination and guarantee system integrity.

- Low hydrogen permeability minimizes energy loss and enhances fuel efficiency.

- Full PEM system compatibility ensures safe and efficient integration with Proton Exchange Membrane (PEM) technology.

- Excellent thermal stability maintains performance even under extreme temperature variations.

Battery Electric Vehicles BEV

We develop silicone hose solutions for Battery Electric Vehicles, optimized for cooling, insulation, and thermal management in high-performance electric systems.

- Superior thermal conductivity enhances battery cooling efficiency and extends lifespan.

- High electrical insulation ensures safe operation of high-voltage components.

- Flexible and durable design resistant to vibration, aging, and harsh environmental conditions.

- Custom shapes and sizes tailored to specific EV architectures for maximum integration efficiency.

Electrolyzers

- Exceptional chemical resistance withstands aggressive electrolytic environments.

- High material purity prevents contamination and maintains gas integrity.

- Thermal and pressure resistance suitable for continuous industrial operation.

- Custom-engineered for safety, supporting reliable hydrogen generation and storage processes.

Our Solutions: Advanced Inner Layer Formulations

To meet the demanding requirements of FCV, BEV, and electrolyzer systems, we offer a range of inner layer formulations for our hoses:

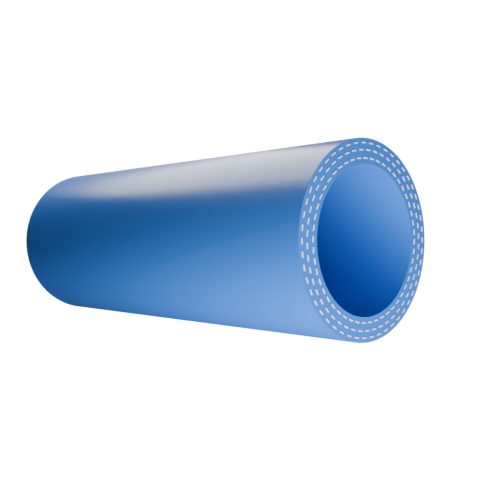

Inner Layer:

VMQ – Peroxide Cured

External Layers:

VMQ – Peroxide Cured

A cost-effective solution with good thermal resistance, suitable for general automotive use. It may release by-products during curing, increasing the risk of leaching. Post-curing is often required to reduce extractables.

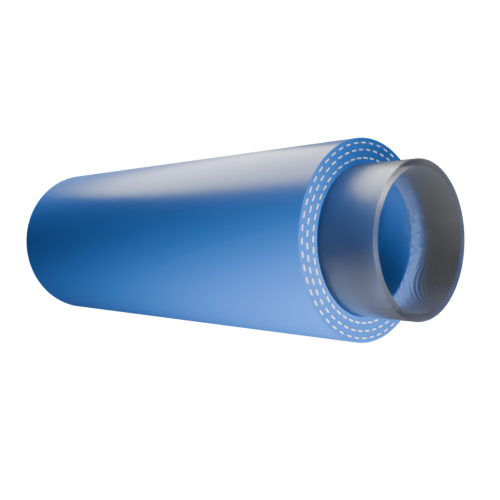

Inner Layer:

VMQ Platinum Cured Translucent

External Layers:

VMQ Platinum Cured

Offers ultra-high purity with minimal extractables and leachables. Preferred for critical fluid paths and fuel cell systems where contamination must be minimized.

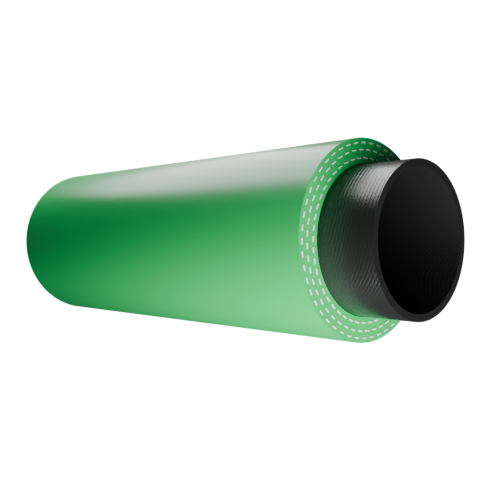

Inner Layer:

FKM (Fluoroelastomer):

External Layers:

VMQ Peroxide Cured

Provides excellent chemical resistance and significantly lower gas permeability compared to silicone. Ideal for hydrogen systems and aggressive fluids.

Looking for Something More Custom?

If our standard solutions don’t fully meet your requirements, or if you need a more tailored approach, we’re here to help you. 📣 Visit our FABLAB

Our technical team is ready to support you in developing a custom-made product that fits your exact specifications. From material selection to advanced design and prototyping, we’ll work with you to create the perfect solution.

Enter the FABLAB and start your custom project today.